| |

Just for Fun

Popsicles were invented by accident by an 11-year-old boy named Frank Epperson in 1905. He accidentally left a mixture of powdered soda and water, with a stirring stick, on his porch, and awoke the next morning to find a frozen pop!

|

|

Quick Tip

Supporting a roll of belting on a cradle or stand will prevent uneven stress, whereas storing it on the ground is bad practice.

|

|

| |

Jason Hicks

Material Planner / Production Lead

22 years with Martin

How you might

interact with Jason:

Jason works directly with customer service to fulfill customers' needs and solve problems should they arise. He makes sure we meet our customers' requirements on time and free of defects.

Favorite thing about Martin:

The people I work with everyday, there truly is a great group of employees here at Martin.

Favorite thing about position/job:

I enjoy being able to help solve problems we come across in the material planning stage as well as the manufacturing process.

Something I want

customers to know:

Thank you. Without YOU, none of this would be possible.

New Sealing System Reduces Spillage & Maintenance Labor

Platte Generating Station (PGS), a coal-fired power plant located in Nebraska handling a volume of approximately 30,000 tons per month of PRB coal, was experiencing failures of the rubber/fabric seals at the top of the chute wall on its Train Unload Vibratory Feeder. Workers had to clean up at least once per month, and the spillage created a potential workplace hazard.

After a months-long trial period running several tons of coal, the Martin® ApronSeal™ Skirting has yet to require replacement. There has been a considerable reduction in spillage and maintenance labor.

Read full article

NOBODY BUT MARTIN MAKES THIS GUARANTEE. NOBODY!

This appeared in the April 1983 issue of Coal Mining & Processing Magazine. 33 years later, and we are still following the same principles the company adhered to in 1944 upon founding. In fact, we still have the same GUARANTEE! We are proud of the fact that we ensure our customers' complete satisfaction. As stated in 1944 and 1983, and still believed today, "it is our strongest way of assuring customers that Martin Engineering will stand by them after the sale." We have built upon the original guarantee and expanded our assurance by adding/updating guarantees throughout the years. Bottom line: we stand behind our products and it shows through our commitment to our long-standing guarantee(s).

Pay it Forward!

The Martin Wellness committee designated June "Pay it Forward" month. Martin Employees took part in Adopt-a-Highway and cleaned up over 20 bags of trash.

Martin held its first "Pay It Forward" town cleanup event last weekend in our hometown of Neponset. Employees donated their time and efforts to help local residents clean up and fix up their homes. The group worked on everything from yard work to staining and painting, cleaning gutters and porches, washing windows, building a handicap entrance ramp and more!

|

|

Martin is expanding upon its series of Foundations™ books by writing the first-ever book dedicated solely to conveyor safety.

Foundations™ for Conveyor Safety

The Global Best Practices Resource for Safer Bulk Material Handling

This 300+ page textbook is devoted exclusively to conveyor system safety, and will be available digitally in a few weeks.

Designed to educate readers by identifying hazards, danger zones, and unsafe work practices around conveyors - helping raise awareness among management, operations, and maintenance personnel. By using our collection of worldwide best practices, you will be able to calculate your Return on Safety™.

- Section 1: Hazards and Danger Areas

An introduction into the hazards of belt conveyors and unsafe work practices around conveyors.

- Section 2: Hardware Solutions

Examines switches and sensors, alarms, signage, conveyor guards, conveyor fires, access and other safety solutions designed to protect workers and increase production.

- Section 3: Safe Work Practices

Discuss best concepts to working safely around conveyors, dealing with conveyors, fugitive material and cleanup and conveyor safety training.

- Section 4: Risk Assessment

Includes the Conveyor Safety Census, risk assessment using CEMA methodology, root cause analysis and job hazard analysis.

- Section 5: Building Better (Safer) Conveyors

Learn what to consider when preparing typical specifications for Cleaner, Safer and more Productive Conveyors.

- Section 6: The Payback (Accounting for Safety, etc.)

Connect the dots and calculate the payback for Safety at your plant.

REGISTER to receive your advanced digital copy and be one of the first to use this valuable resource.

Martin® QB1™ Cleaner HD

The next generation of belt cleaning technology delivers extreme cleaning and extensive blade life – at the lowest cost!

- Costs up to 35% less than competitors’ list price

- Simplified manufacturing process reduces the cost of ownership while providing the same amount of usable area

- Utilizes patented CARP (Constant Angle Radial Pressure) technology to maintain consistent cleaning throughout all stages of blade life

- Features no-tool replacement process safely performed by one person in less than five minutes

- Can be retrofitted onto any Martin system as well as competitive systems

- Covered by FOREVER GUARANTEE: No-cost replacement tensioners and mainframes as long as Martin® belt cleaner blades are used, helping to maintain maximum performance

More Information

|

Brad Pronschinske

Director - Air Cannon Business Group

18 years of industry experience

|

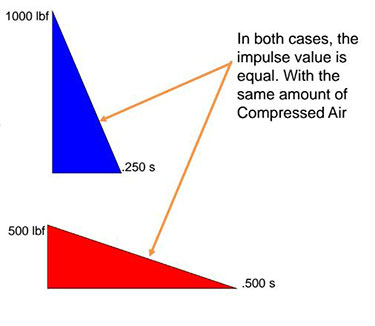

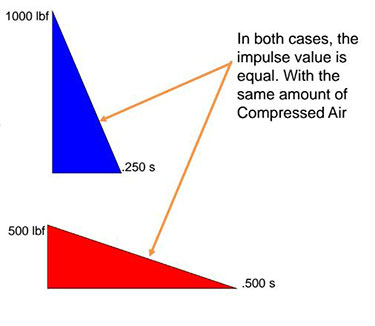

Impacting Air Cannon Blast Force

There are many aspects that go into the duration and force received from air cannons. Below are 3 areas that have a direct impact on your air cannon's blast force. Understanding these concepts will allow you to gain the most from your air cannon(s).

1. Valve Design - Maximize the peak force of the blast

2. Air Pressure - Increasing air pressure will increase the peak force of your blast regardless of tank size

3. Tank Size - The size of the tank controls the duration of your blast and has a small impact on your peak force. You will have a longer blast with a 150L tank compared to a 35L tank

Peak force occurs immediately after the valve is opened.

If you have questions regarding air cannons, contact Brad at 800-544-2947 extension 503.

What do YOU want to read?

|

|