Resources

| PDF - Printable Version of Case Study | Download |

| Products Used | CleanScrape® Primary Cleaners |

|---|---|

| Product Types Used | Belt Cleaning Solutions , Primary Belt Cleaners |

| Industry | Mining |

| Customer | Bharat Aluminium Company Limited (BALCO), Korba, Chhattisgarh, India |

Balco power plant, with a volume of 5000 tonnes (5511 tons) per day of coal, was experiencing spillage caused by excessive carryback. With no space for a secondary or tertiary cleaner, dust and fines bypassed the primary cleaner blade and spilled along the belt path. Piling around the structure and along walkways, the spillage restricted access and created a walking hazard. Dust and fines fouled rolling components leading to premature equipment replacement. Labor for cleanup and maintenance, plus product loss, raised the cost of operation. Maintenance also required unscheduled downtime, further raising costs. Managers tried several blades to find a solution and approached Martin Engineering in search of one that fit their needs.

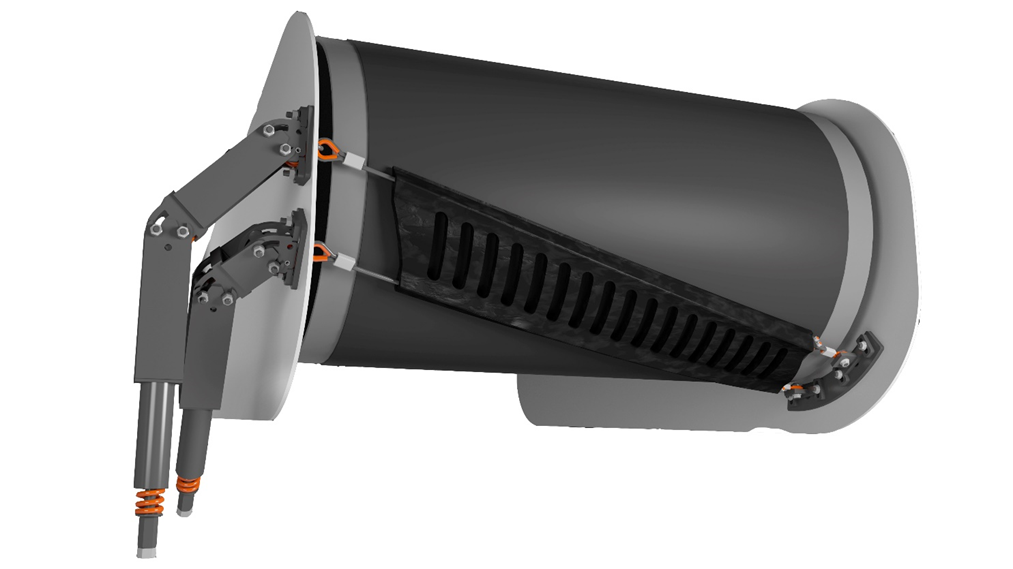

The Martin Engineering India team visited the site and performed an assessment. After showing the Martin® CleanScrape® Primary Cleaner to operators, they scheduled an installation. Designed for the heaviest applications, it features a matrix of rugged tungsten carbide scrapers that are easy on mechanical splices and provide better cleaning efficiency throughout the blade's life than most traditional blade designs. The CleanScrape was installed diagonally to form a 3-dimensional curve around the head pulley at 17-19 degrees using double tensioners. Field testing has revealed the blade typically delivers up to 4x the service life of urethane primary cleaners, without ever needing re-tensioning after adjustments following a performance review.

After a few months in service, operators report that the cleaners have significantly reduced the amount of carryback and improved safety. With a drastic reduction in spillage, the volume of material piling in walkways and fouling equipment has been properly mitigated. "We are impressed by how well the solution performs compared to our previous attempts," said an operator close to the project. No need for re-tensioning or blade replacement meant downtime from maintenance has been reduced considerably. Reduced maintenance labor and product loss has lowered the cost of operation, offering a short ROI.

| PDF - Printable Version of Case Study | Download |