| Products Used | CleanScrape® Cleaner |

|---|---|

| Product Types Used | Belt Cleaning Solutions , CleanScrape® Cleaner |

| Industry | Quarrying |

| Customer | Rock Quarry in USA |

Problem

A U.S. rock quarry was experiencing carryback on one of its conveyors. The system transfers thousands of tons of 4-in. (101 mm) minus aggregate on a 30-inch wide (762 mm) belt traveling 420 feet (128 m) at 250 fpm (1.27 mps) from one crusher to another. The crusher-to-conveyor process results in the aggregate being reduced to .5 inch minus sand. Leading from the quarry to the interior of the facility, the outdoor portion of the belt was exposed to extreme weather, even though it is covered. Material adhered to the return side of the belt, collected around the mainframe and gummed up rollers, requiring downtime for maintenance and raising the cost of operation.

Solution

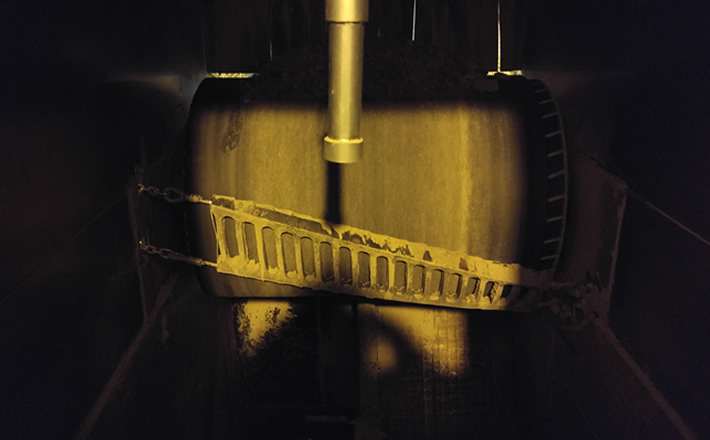

Martin Engineering showed managers the latest innovation in belt cleaning technology, the CleanScrape® Cleaner. Technicians needed to drill just four small holes required for mounting. Installed diagonally across the head pulley, it forms a three dimensional curve that allows the matrix of tungsten carbide scrapers to exert a low contact pressure with the belt, but still offer excellent removal of stuck material. Suitable for belt speeds up to 1500 fpm (8 m/s) with vulcanized splices and 800 fpm (4 m/s) if mechanically spliced, the light touch of the cleaner glides safely over splices while still effectively dislodging material and reducing carryback.

Results

Having installed the CleanScrape® Cleaner on the system with the most carryback and experiencing instant and measurable results, operators immediately had one installed on a second conveyor and have ordered 5 more. “For our application this has been the best belt cleaner we have used, especially with our wet and sticky material,” said a company supervisor. “We are extremely satisfied and plan on installing quite a few more within our plant.” Operators say that the CleanScrape® Cleaner has reduced the labor needed for cleanup and improved system efficiency, and they expect a longer service life than previous cleaners.

We've solved your problem somewhere before!

While your problem seems unique and frustrating, with 70+ years of solving similar problems around the world, and with the most experienced and educated people on our teams, we can assure you that we’ve “Been There, Done That.” At least close enough to know what needs to be done next and adjust for your situation.

Put Us To The Test For Free! Let Us Give You a Solution.